We’re here to help you optimize your process heating equipment or system to ensure peak performance, maximize uptime and increase profitability. Not to worry Blackstar Solutions offers complete support for all of your operations and maintenance needs. We understand that every wasted minute impacts the bottom line. The difference isn’t just in what we do — it’s how we do it. Our team of service professionals provide fast and precise support to keep your operation running.

Services offered:

- NFPA Checks

- Burner tuning

- System tuning

- Training

- Equipment instillation (mechanical and electrical)

- Troubleshooting

- Engineering studies

Aftermarket Services

At Blackstar Solutions, our aftermarket services are what set us apart from everyone else in the industry. Our customers are our top priority and ensuring that they have the least amount of downtime possible is what sets us apart from the rest. Our maintenance, retrofit/upgrade, and OEM replacement part services are available to ensure your process heating equipment continues to run reliably and safely. Simply put Blackstar Solutions is your total aftermarket solution!

Products We Service

Blackstar Solutions works on and supplies parts for a wide range of products for industrial heating. Below are some types of process heating systems that we service on a regular basis and how they work.

Thermal Fluid Systems

Thermal fluid heating systems are used to heat a fluid to a high temperature and then transfer that heat to a process or application. These systems are often used in industrial processes such as manufacturing, oil and gas production, chemical processing, and food processing.

The thermal fluid used in these systems is typically a synthetic oil or a glycol-based fluid, which has excellent thermal stability and can be heated to high temperatures without breaking down. The fluid is circulated through a closed loop system, which includes a heater, pump, and a heat exchanger. The heat exchanger is used to transfer the heat from the fluid to the process or application.

One of the advantages of thermal fluid heating systems is that they can be used in a wide range of temperatures, from -80°C to 400°C or higher. They also have a high degree of control over the temperature, which makes them ideal for processes that require precise temperature control.

Overall, thermal fluid heating systems are a reliable and efficient way to heat fluids for industrial processes and applications.

Biomass Energy Systems

A biomass energy system is a renewable energy system that uses organic matter, such as wood chips, agricultural waste, or other plant matter, as a fuel source to generate heat or electricity. Biomass energy is considered renewable because the organic matter used as fuel can be replenished through natural processes.

There are several different types of biomass energy systems, including:

- Direct combustion systems: This is the simplest and most common type of biomass energy system, where the biomass is burned to produce steam, which is then used to generate electricity or heat.

- Gasification systems: This process involves heating the biomass in a low-oxygen environment to produce a gas that can be burned to generate electricity or heat.

- Pyrolysis systems: In this process, the biomass is heated in a low-oxygen environment to produce a liquid or gas that can be burned to generate electricity or heat.

- Biochemical conversion systems: This process involves using microorganisms or enzymes to convert the biomass into fuels such as ethanol or biodiesel.

Biomass energy systems have several advantages over fossil fuels. They are renewable, reduce greenhouse gas emissions, and can be used in rural areas where other energy sources may not be available. Additionally, biomass energy systems can help to reduce waste by using organic matter that would otherwise be discarded.

However, biomass energy systems also have some disadvantages. They can be expensive to install and maintain, and the process of producing biomass fuels can sometimes compete with food production. Additionally, the use of biomass as a fuel source can result in air pollution if not properly managed.

Overall, biomass energy systems are an important renewable energy source that can provide a sustainable alternative to fossil fuels.

Process Bath Heaters

Process bath heaters are used to heat liquids or gases that are used in industrial processes. These heaters are typically used in tanks or baths where the liquid or gas is stored and heated to a specific temperature. The heated liquid or gas is then used in various industrial processes, such as chemical processing, oil and gas production, metal fabrication, and power generation.

Process bath heaters can be powered by a variety of energy sources, including electricity, natural gas, and propane. They are designed to provide precise temperature control and can be operated manually or controlled by a digital thermostat or controller.

Overall, process bath heaters are an essential component of many industrial processes, providing reliable and efficient heating for liquids and gases used in manufacturing and other applications.

Direct Fired Heaters

Direct fired heaters are a type of industrial heating equipment that are used to heat gases or liquids using a direct flame. These heaters are commonly used in a variety of industries, including oil and gas, chemical processing, and food processing.

In direct fired heaters, a burner is used to directly heat the process fluid or gas. The burner is typically fueled by natural gas, propane, or diesel fuel. As the fuel burns, the heat is transferred directly to the process fluid or gas, heating it to the desired temperature.

There are several different types of direct fired heaters, including:

- Radiant heaters: These heaters use a series of burners to create a radiant heat source. The process fluid or gas is passed over the radiant heat source, which heats it directly.

- Convection heaters: These heaters use a combination of radiation and convection to heat the process fluid or gas. The heat from the burner is transferred to a heat exchanger, which then heats the process fluid or gas through convection.

- Indirect heaters: These heaters use a heat exchanger to heat the process fluid or gas. The burner heats a separate fluid, which is then passed through a heat exchanger, where the heat is transferred to the process fluid or gas.

Direct fired heaters have several advantages, including high efficiency and low operating costs. They can be used to heat a wide range of fluids and gases, and are capable of heating large volumes of fluid or gas quickly.

Overall, direct fired heaters are an important type of industrial heating equipment, providing reliable and efficient heating for a wide range of applications.

Automation Solutions

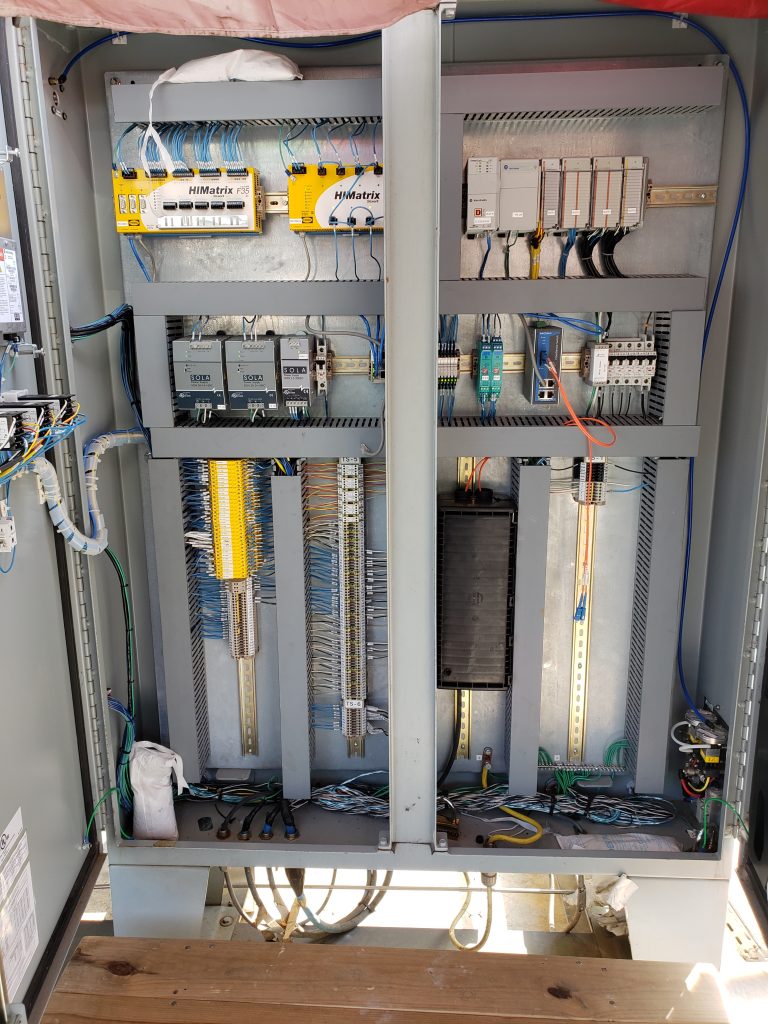

Over time, PLCs and control panels may become outdated or require upgrades in order to keep up with changing technology or manufacturing needs. Upgrading a PLC or control panel can provide several benefits, including improved efficiency, increased reliability, and enhanced safety.

PLC and control panel upgrades typically involve replacing outdated components with newer, more advanced technology. This may include upgrading hardware components, such as processors and memory modules, or software components, such as programming languages and operating systems.

When upgrading a PLC or control panel, it is important to work with an experienced technician or engineer who can evaluate the existing system and determine the best upgrade strategy. They can help identify areas that need improvement and recommend the most appropriate components and technologies for the upgrade.

Some common reasons for PLC and control panel upgrades include:

- Obsolescence: Older components may become obsolete and difficult to replace, which can lead to decreased reliability and higher maintenance costs.

- Capacity: As production needs increase, the existing system may not be able to handle the required load, resulting in decreased efficiency and decreased production rates.

- Safety: Outdated components may pose a safety risk to operators or equipment, and upgrading to newer components can improve safety and compliance with regulations.

Overall, PLC and control panel upgrades can provide significant benefits for industrial processes, improving efficiency, reliability, and safety while reducing maintenance costs and downtime.

Waste Heat Recovery

Waste heat recovery refers to the process of capturing and utilizing heat that would otherwise be wasted and lost to the environment. Waste heat can be generated in a variety of industrial processes, including manufacturing, power generation, and transportation.

By capturing waste heat and converting it into useful energy, waste heat recovery can provide several benefits, including:

- Increased energy efficiency: By using waste heat to generate additional energy, waste heat recovery systems can improve the overall energy efficiency of a process, reducing the amount of fuel or electricity needed to produce the same output.

- Cost savings: By reducing the amount of fuel or electricity needed to produce the same output, waste heat recovery systems can also provide cost savings in energy bills.

- Reduced environmental impact: By utilizing waste heat that would otherwise be lost to the environment, waste heat recovery systems can reduce greenhouse gas emissions and other environmental impacts associated with energy production.

There are several different methods for capturing and utilizing waste heat, including:

- Heat exchangers: Heat exchangers are devices that are used to transfer heat from one fluid to another. In a waste heat recovery system, a heat exchanger can be used to capture heat from a hot process fluid and transfer it to a cooler fluid that can be used to generate additional energy.

- Organic Rankine Cycle (ORC) systems: ORC systems use a working fluid with a lower boiling point than water to generate power from waste heat. The waste heat is used to vaporize the working fluid, which is then used to drive a turbine and generate electricity.

- Absorption chillers: Absorption chillers use waste heat to generate cooling for air conditioning or refrigeration. The waste heat is used to drive a process that generates a cooling effect, which can be used to cool air or refrigerate products.

Overall, waste heat recovery is an important strategy for improving energy efficiency, reducing costs, and reducing environmental impacts in a variety of industrial processes.

High-Pressure Steam Generators

A high-pressure steam generator is a type of boiler that produces high-pressure steam for industrial processes. High-pressure steam generators are commonly used in power generation, chemical processing, and oil and gas industries, among others.

The operation of a high-pressure steam generator involves the heating of water to generate steam at high pressures and temperatures. This process is typically achieved using a combination of combustion and heat transfer. Fuel is burned in a combustion chamber, heating water in a boiler to produce steam. The steam is then sent through a series of pipes and turbines to generate electricity or drive industrial processes.

High-pressure steam generators can operate at pressures ranging from 15 to 800 psi and temperatures ranging from 212 to 850 degrees Fahrenheit. The design of a high-pressure steam generator is typically customized to meet the specific needs of the industrial process it is used for.

The advantages of using a high-pressure steam generator include:

- High efficiency: High-pressure steam generators can achieve high levels of energy efficiency, reducing energy costs and environmental impacts.

- Reliable operation: High-pressure steam generators are designed for reliable and continuous operation, providing consistent steam for industrial processes.

- Versatility: High-pressure steam generators can be customized to meet the specific needs of a variety of industrial processes.

- Safety: High-pressure steam generators are typically designed with safety features to prevent accidents and ensure safe operation.

Overall, high-pressure steam generators are an important technology for many industrial processes, providing reliable and efficient steam for power generation and industrial applications.

Electric Process Heaters

Electric process heaters are devices that use electricity to generate heat for industrial processes. They are used in a variety of applications, including heating liquids and gases, drying materials, and melting metals.

Electric process heaters work by converting electrical energy into heat energy. This is typically achieved by passing an electric current through a heating element, such as a resistance wire or a ceramic heater. The heating element is placed in contact with the material to be heated, transferring heat to it through conduction or radiation.

There are several different types of electric process heaters, including:

- Immersion heaters: Immersion heaters are designed to be immersed directly in a liquid or gas to heat it. They are commonly used in applications such as oil heating, chemical processing, and water heating.

- Circulation heaters: Circulation heaters are designed to heat a liquid or gas as it flows through a pipe or vessel. They are commonly used in applications such as heating water or oil in industrial processes.

- Infrared heaters: Infrared heaters use electromagnetic radiation to heat objects without heating the surrounding air. They are commonly used in applications such as drying paints or coatings.

The advantages of using electric process heaters include:

- Energy efficiency: Electric process heaters can achieve high levels of energy efficiency, reducing energy costs and environmental impacts.

- Precise control: Electric process heaters can be controlled with a high degree of precision, allowing for accurate temperature control and process optimization.

- Safety: Electric process heaters are typically designed with safety features to prevent accidents and ensure safe operation.

- Ease of maintenance: Electric process heaters are generally easy to maintain and repair, with no need for fuel storage or handling.

Overall, electric process heaters are an important technology for many industrial processes, providing reliable and efficient heat for a variety of applications.