Automation and controls play a critical role in your process by improving efficiency, productivity, safety, and quality of products. Blackstar Solutions has a team of highly trained personnel that can evaluate your system to determine if an automation or controls upgrade might be right for your process. Having the right automation and controls for your process ensures that your system is running safe and at it’s optimal limits.

The components of an automation and controls system that may need upgrading include:

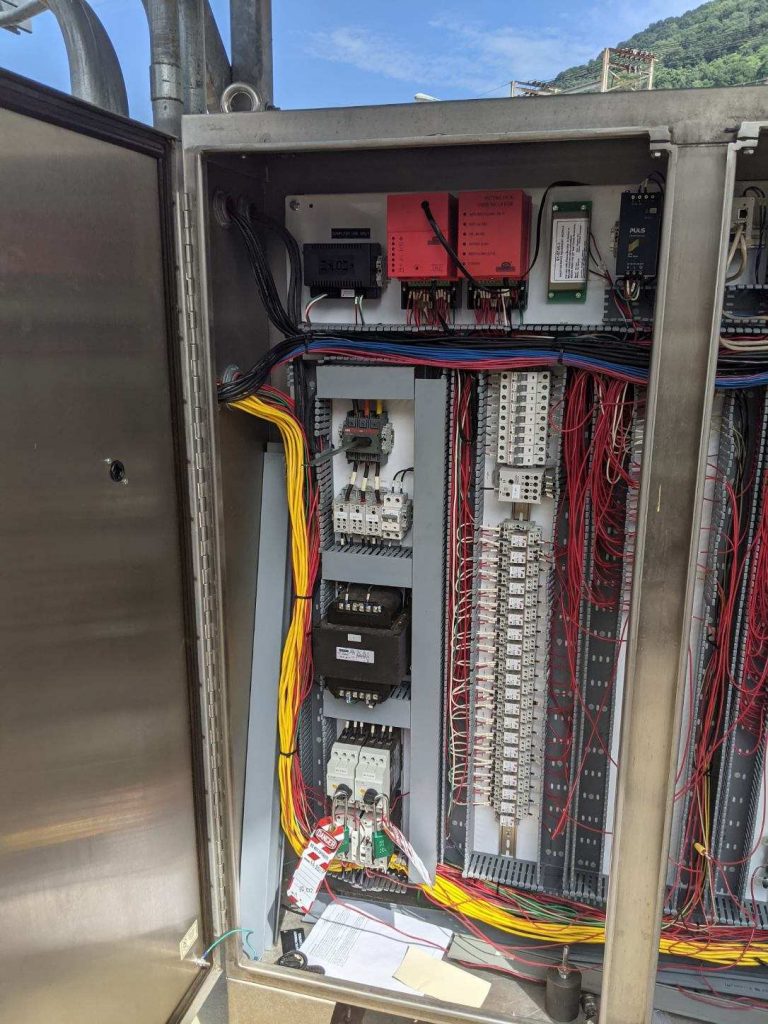

- Sensors and Actuators: Sensors are used to measure process variables such as temperature, pressure, flow rate, and level, while actuators are used to control the process variables by adjusting valves, pumps, motors, and other devices.

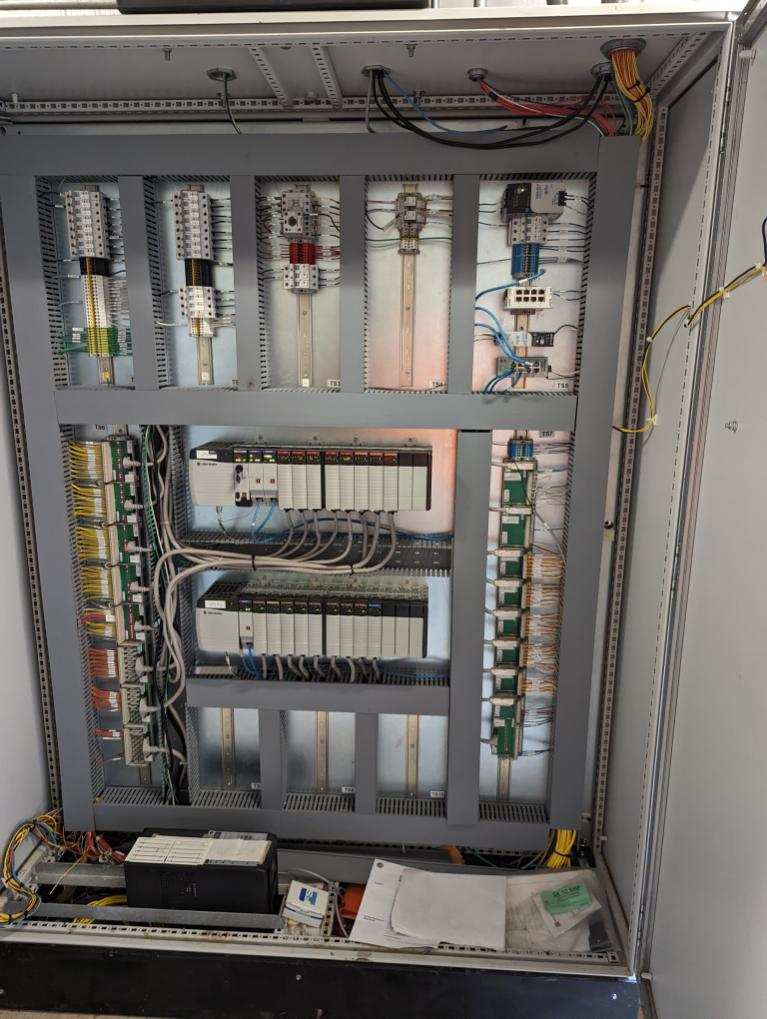

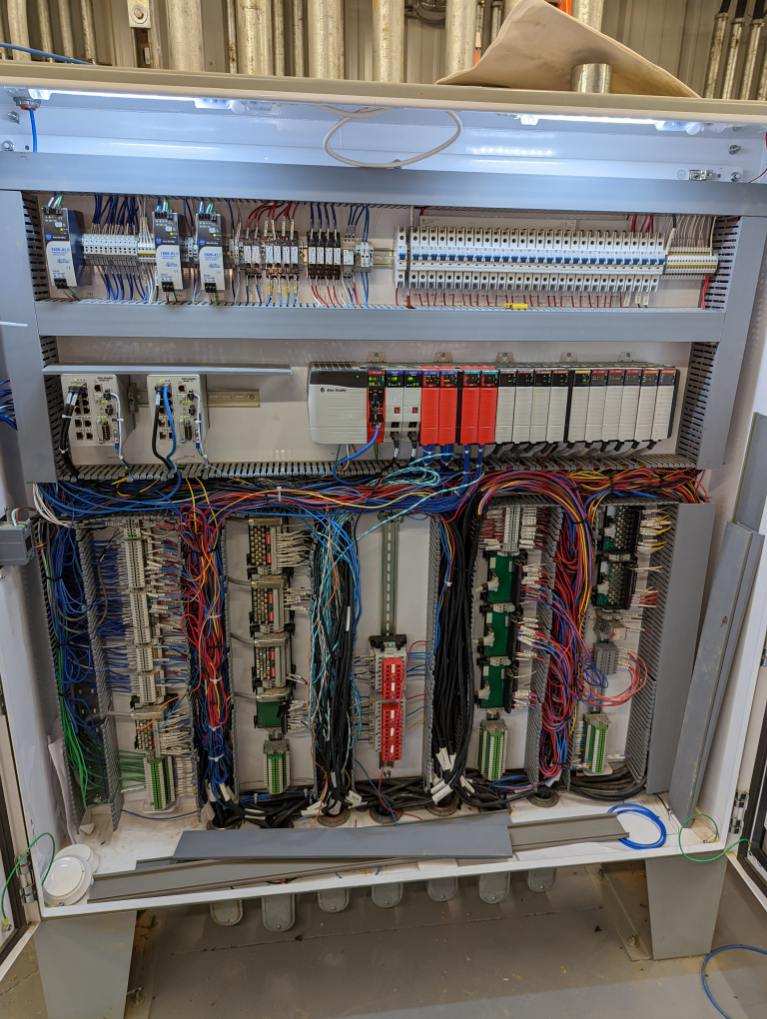

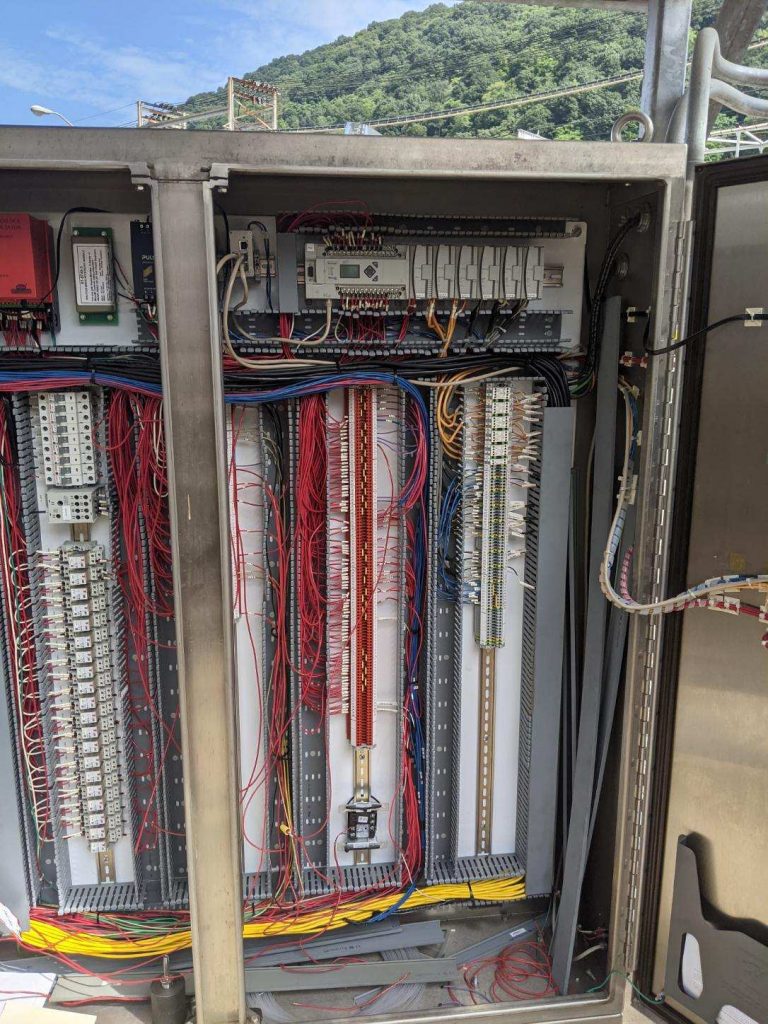

- Programmable Logic Controllers (PLCs): PLCs are industrial computers that are programmed to automate the control of various processes. They receive signals from sensors and provide output signals to actuators to regulate the process variables.

- Human Machine Interfaces (HMIs): HMIs are graphical user interfaces that allow operators to monitor the process variables and control the process through a touch screen, buttons, or other input devices.

- Supervisory Control and Data Acquisition (SCADA) Systems: SCADA systems are software applications that collect and analyze data from various sensors and PLCs, and provide real-time information and alerts to operators and managers.

- Distributed Control Systems (DCS): DCS is a control system that uses multiple PLCs and HMIs to control various processes across the industrial plant. It provides a centralized control and monitoring system that can be accessed from different locations.

Here at Blackstar Solutions we offer complete automation solutions to fit your needs. Whether you just need one of our engineers to create a set of electrical drawings, or perhaps you need the services of our UL listed panel shop to build your panel from your own drawings, we’ve got you covered.